The key technical

The key technical

Modern system integration technology

Advanced modern system integration technology mainly consists of unit process integration and computer information integration. Since the optimal units don’t necessarily result in the optimal system in a complex system, the combination of unit processes (series connection and parallel connection) must take into full account quality control, logistics management, energy consumption, operation, etc. of the whole system. By means of the unit technology system integration and optimization software, the Engineering Center has used computers to achieve the optimization of production scheduling and process conditions, focused on tackling the key “bottleneck” problems that restrict the industrial development, and developed a series of modern system integration technologies.

The system integration technology centered on multi-stage countercurrent extraction, macroporous resin adsorption and separation, low temperature membrane concentration and spray drying, solves the key technical problems of precise feeding of traditional Chinese medicine compound preparations

Macroporous adsorption resin technology can efficiently separate and purify the effective components of traditional Chinese medicine, and it is an important modern preparation technology of traditional Chinese medicine. Kunxian Capsule is a first-line Chinese patent medicine to address proteinuria at present, but its therapeutic window is narrow, and it is critical to control the content and proportion of the extracts of four medicinal herbs. In order to solve the problem of narrow therapeutic window of Kunxian Capsule, the integrated technology of multi-stage countercurrent extraction, macroporous resin adsorption and separation, low temperature membrane concentration and spray drying has realized the precise control of the extracts. And strict quality standards are formulated to mix the materials with precise content and produce Kunxian Capsule raw materials with good quality and excellent efficacy, which are exclusive products in China. The application of this technology has provided a demonstration for the new drugs development of traditional Chinese medicine, the secondary transformation of famous and high-quality products, and the upgrade and modernization of the production process of traditional Chinese medicine, and advanced the modernization and industrialization process of traditional Chinese medicine. (2) The system integration technology centered on supercritical carbon dioxide extraction, high efficiency adsorption and separation, nanofiltration membrane concentration and freeze drying, tackles the “bottleneck” technical problem for the industrialization of phospholipids for injection and breaks the import monopoly.

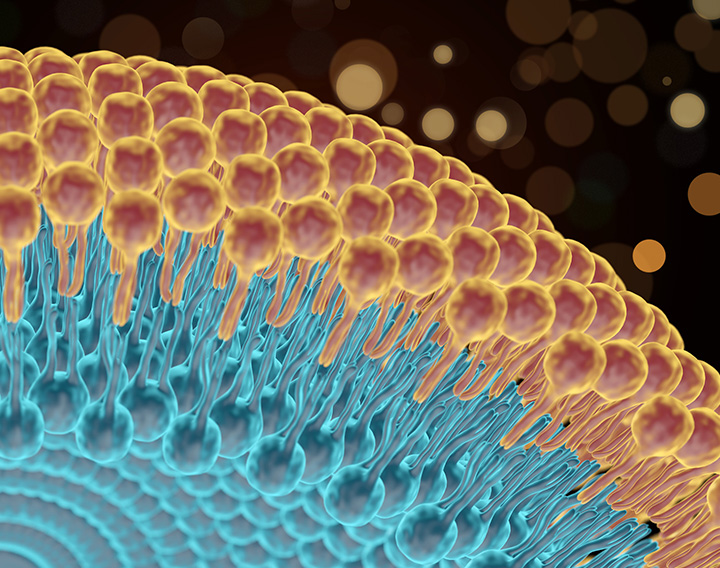

The system integration technology centered on supercritical carbon dioxide extraction, high efficiency adsorption and separation, nanofiltration membrane concentration and freeze drying, tackles the “bottleneck” technical problem for the industrialization of phospholipids for injection and breaks the import monopoly.

The integrated technology of supercritical carbon dioxide extraction, high efficiency adsorption and separation, nanofiltration membrane concentration and freeze drying has addressed a series of technical problems such as the control of harmful impurities and purity, the proportion control of functional components, and oxidation control of phospholipids for injection. It has first achieved the industrialization and listing of egg yolk lecithin for injection in China, first completed the FDA registration (Registration No.: DMF035483) in China, addressed the problems of industry chain and supply chain security for fat emulsion in China; realized the industrialization and listing of egg yolk phosphatidylcholine for injection, broken the foreign monopoly, and solved the “bottleneck” industry restriction problem of foreign imported products.

The system integration technology centered on multi-stage directional and efficient adsorption and multi-stage filtration tackles the “bottleneck” technical problem for oil series for injection and breaks the import monopoly of high-end oil for injection.

Medicinal oils, especially nutritive and functional oils such as Brucea javanica oil, Coix seed oil, olive oil and fish oil, are currently the research hotspots. The difference of their functions ultimately depends on the different types of fatty acids. Many functional oils have different fatty acid ratios, so they can meet different nutritional and functional requirements. However, due to their complex composition and easy oxidation and deterioration, the fatty acid ratio control and quality control of oils for injection have always been the bottleneck for the development of the industry. The Engineering Center has adopted the integrated industrial production technology centered on multi-stage directional and efficient adsorption and multi-stage filtration, solved the key common technical problems that restrict the industrialization of oils for injection, such as oxidation index control and fatty acid ratio control, completed the industrialization of olive oil for injection and fish oil for injection, broken the foreign monopoly, and solved the “bottleneck” industrial problem of blockade by foreign technology and products.

The system integration technology centered on multi-stage countercurrent extraction, preparative industrial chromatography and semi synthesis, tackles the key technical problems such as plant-derived compound impurity control.

Vinca alkaloids anti-tumor drugs generally have the problem of low yield and purity. To solve this problem, the application of integrated industrial technologies including multi-stage countercurrent extraction, preparative industrial chromatography and semi synthesis has made a major breakthrough in addressing common technical problems of industrialization difficulties in Vinca alkaloids APIs such as Vincristine and Vinorelbine, promoted Vinorelbine Tartrate to pass the EU CEP certification and obtain the first CEP certificate of plant anti-tumor drugs in Guangdong Province, driven the industrialization and internationalization of Vinca alkaloids oncology APIs and intermediates, and further driven the development of domestic Vinca planting industry. To bridge the gap of clinical medication for autoimmune disease Sjogren's syndrome, this integrated technology has been used to develop the CP-25, Class 1 innovative drug of plant origin. The successful development will fill in the gap of curative drugs for Sjogren's syndrome in clinical practice.